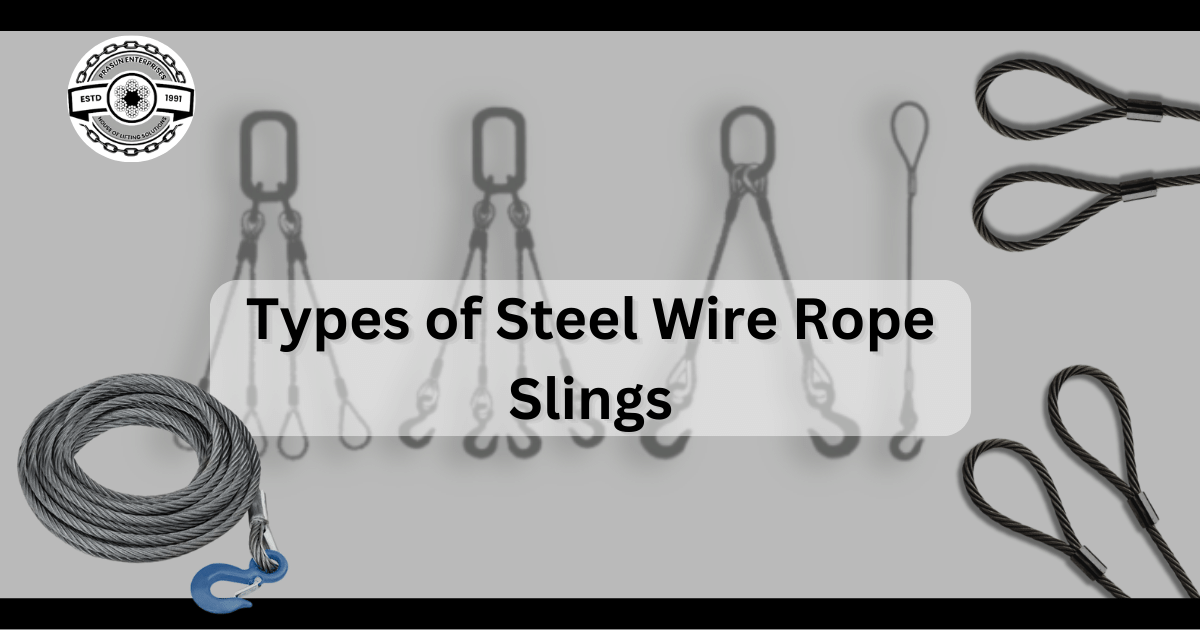

In industries that depend on heavy lifting and secure load transportation, the choice of lifting equipment is basic. Steel wire rope slings, conforming to IS: 2762 standards, are a foundation of security and efficiency. These flexible tools come in different types, each custom-made to specific applications and requirements. In this blog post, we’ll dive into the different types of steel wire rope slings as conform by IS: 2762, shedding light on their special characteristics and how they cater to desires of different industries.

Types of Steel Wire Rope Slings

- Single Leg Slings: Single leg slings are the best and most commonly utilized type of steel wire rope sling. They consist of a single length of wire rope with an eye or hook attachment at one end and frequently a hook or fitting at the other. Single leg slings are flexible and can be utilized for a wide range of lifting applications, from vertical lifting to choker and basket hitches. They are ordinarily utilized when a single attachment point is sufficient to support the load.

- Multi-Leg Slings: Multi-leg slings, as the title suggests, include multiple legs or branches of steel wire rope that merge into a single attachment point. These slings are utilized for lifting unpredictably shaped or unequal loads that require more stability. Multi-leg slings give improved load distribution and can be customized to suit particular load shapes. Common setups include two-leg, three-leg, and four-leg slings.

- Endless Slings (Grommet Slings): Endless slings, moreover, known as grommet slings, are built from a continuous loop of wire rope, with the ends joined together to create a secure, endless ring. They are highly adaptable and versatile for different applications, counting those where choker hitches are required. Endless slings are well-suited for utilization in circumstances where load assurance and surface contact are critical. Their endless design minimizes wear and tear on the sling itself.

- Eye and Eye Slings: Eye and eye slings are made from a single length of wire rope that forms two eye loops at each end. These loops give helpful connection points for hooks, shackles, or other lifting equipment. Eye and eye slings are flexible and are frequently utilized in vertical or basket hitches. They are known for their adaptability and ease of use.

- Adjustable Bridle Slings: Adjustable bridle slings comprise of different legs, each with an adjustable fitting that permits the length of each leg to be customized. This adjustability makes them perfect for lifting loads with changing measurements or for achieving exact load control. Adjustable bridle slings are frequently utilized in applications where the center of gravity of the load must be precisely controlled.

- Drum Handling Slings: Drum handling slings are specialized slings planned for lifting and transporting cylindrical loads, such as drums or barrels. They are prepared with chime hooks or special drum attachments that safely hold and stabilize the load. Drum handling slings are vital in industries where the movement of drums is a common operation, such as manufacturing and chemical processing.

- Pipe Handling Slings: Pipe handling slings are custom-made for lifting and positioning long, cylindrical loads, such as pipes, tubes, or logs. They include specially designed end fittings that secure the load whereas giving even weight distribution. These slings are commonly utilized in industries like construction, oil and gas, and forestry.

- Basket Slings: Basket slings, also known as choker slings, are designed to be looped around a load, making a basket setup. They are flexible and can be utilized for a wide range of load shapes and sizes. Basket slings are perfect for applications where loads need to be cradled safely, preventing movement or shifting during lifting.

- Specialty Slings: In addition to the standard types of steel wire rope slings mentioned above, there are also specialty slings designed for particular applications. For example, acid-resistant slings are utilized in corrosive situations, whereas high-temperature slings are designed to withstand extreme heat. These specialty slings cater to the unique necessities of industries like chemical handling and foundries.

Conclusion: Selecting the Right Sling for the Work

Choosing the suitable type of steel wire rope sling is vital for secure and efficient lifting operations. Each type of sling offers particular advantages and is custom fitted to particular load shapes, sizes, and situations. By understanding the differences of steel wire rope slings as defined by IS: 2762, industries can make informed choices, guaranteeing the security and reliability of their lifting operations. Whether it’s a single leg sling for clear vertical lifting or a multi-leg sling for complex, irregular loads, the correct sling is the key to accuracy and performance in industries that depend on heavy lifting and secure load transportation.